Once assembled, PCB’s should be protected from handling, moisture, static and human interaction. Here are a few ways to extend the life of your stored printed circuit boards.

It’s not always easy choosing a printed circuit board (PCB) manufacturer, but your patience and careful research will pay off. The right PCB manufacturer will provide you with a quality product that is made from durable materials. But even if you get the best PCB on the market, it still won’t last forever.

On average, PCBs get about 50-70 years of use, under the right conditions. Be sure to follow all of the manufacturer’s recommendations that are included in their terms of use. Let’s learn more about the factors that impact the shelf life of assembled PCBs and how you can make yours last longer.

What Impacts the Shelf Life of Assembled PCBs?

You rely on quality PCBs for your products. If the PCB stops working, your product will, too. Here are the main factors that affect the lifespan of your PCBs.

- Components. The quality of the components used in your design has a significant impact on the board’s life. Choose a PCB manufacturer that uses high quality materials and performs extensive testing.

- Surface finishing. Surface finishing is a PCB plating option that protects the boards while they are being stored, prior to their assembly. HASL is the predominant choice, but others include immersion tin, immersion silver, OSP, ENIG, ENEPIG and gold.

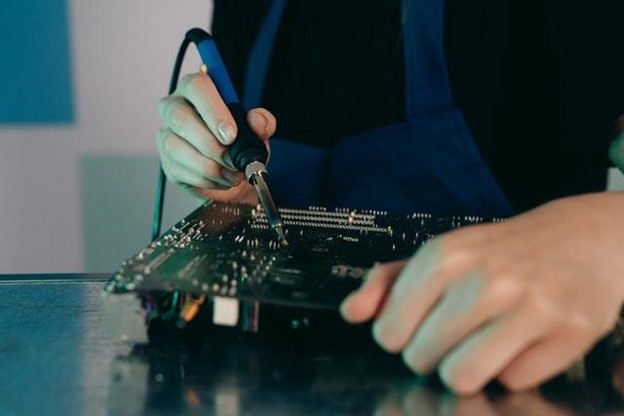

- Soldering. The soldering technique used also makes a difference. Soft soldering is a popular choice, though hard soldering produces stronger joints. Other options include braze soldering, wave soldering and reflow soldering.

- Conformal coating. One of the best ways to protect your PCB is by having a conformal coating applied. Without this coating, your boards may be exposed to contamination during storage.

- Handling. How your PCBs are handled can also introduce contamination. It’s possible for sweat, dirt or chemicals to be left on the board.

- Shipping conditions. Don’t just be concerned with when your boards will arrive – also ask about their shipping conditions. The boards should be delivered in a temperature-controlled vehicle to prevent moisture from forming on the boards. If that is not possible, sealed moisture resistant bagging should be used.

- Storage environment. Lastly, where you store your PCBs affects their lifespan. Store your boards in a moisture barrier bag, in a warm, dry room with low humidity and consistent temperatures. Static guards should always be used when handling the assembled boards.

As you can see, getting your PCBs to last longer requires a team effort. You must choose a reliable PCB manufacturer that uses high quality components, and you must provide the boards with the appropriate storage conditions.

Sonic Manufacturing Technologies is one of the most trusted PCB manufacturers. In fact, we are the largest EMS in Silicon Valley! Everything you need for high quality, efficient PCB manufacturing is under one roof. Contact us today to learn more about our processes.