Fast manufacturing enables product designers and operators to efficiently handle production or manufacturing from start to finish. Fast manufacturing includes layout reviews by manufacturing teams to ensure part manufacturability, readability, and availability of materials and critical components.

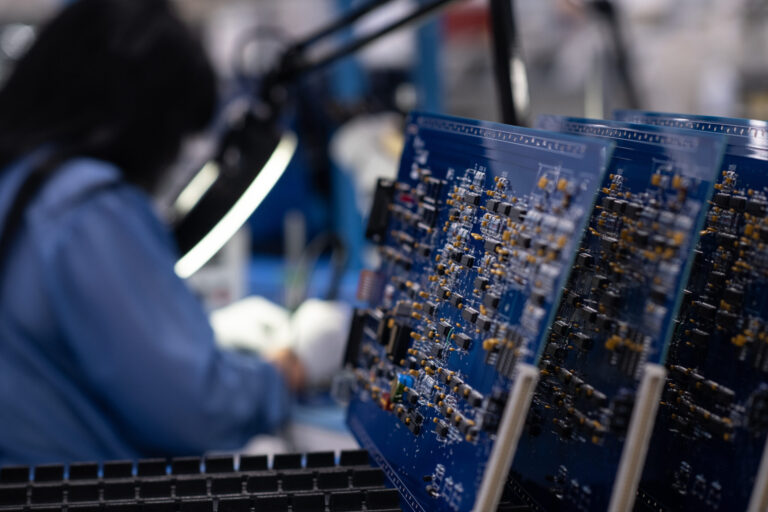

Manufacturing lines that use fast manufacturing ensure quick turn of manufactured end products. A critical element of rapid production is the availability of quality assurance to provide production-ready components – especially circuit boards and electronic components.

In examining printed circuit boards, fast manufacturing enables manufacturing leaders and team players to create top quality, efficient circuit boards.

Circuit boards involve hundreds of components and connections. With fast manufacturing, each component must meet the highest standards of functionality and performance. Even the slightest flaw in components may hinder the successful performance of the entire circuit board.

Sonic Manufacturing, a trusted manufacturer of circuit boards – printed circuit boards, flex circuits, and flex-rigid circuits – uses fast manufacturing to meet production demands and customer satisfaction levels.

Why Fast Manufacturing?

First and foremost, fast manufacturing lowers the overall cost of components. Here at Sonic, fast manufacturing optimizes processes and expedites part manufacturing using rapid prototyping. Rapid prototyping ensures quality results at affordable rates.

In addition, we use fast manufacturing to ensure that the company remains competitive, especially in saturated markets. Alongside production costs, fast manufacturing protects your product’s integrity. Teams and manufacturing lines that rely on rapid production to help optimize prototype production do not just look at cutting costs – sometimes, it’s about surviving in a highly competitive market.

Fast manufacturing or rapid production helps fulfil your custom requests, contract delivery dates, and supplier requests. In addition, we use it to prevent inventory issues because parts, components, and materials can be expedited.

Fast manufacturing has gained credibility in the current global marketplace. And although competitive brands want to excel in part production, operators and shop floors must take their time with manufacturing to the point of failure. Since fast manufacturing helps expedite production processes, this rapid production must be optimized to meet quality and timely output.

Trusted manufacturers like Sonic leverage rapid production processes to save time and money on front-end details. Fast manufacturing uses rapid prototyping to discover specific design features that slow down manufacturing and compromise the end output.

Some of the ways we use fast manufacturing include:

- Rapid prototyping. To eliminate errors and safeguard product integrity throughout the development cycle.

- 3D printing. Also called additive manufacturing, 3D printing is a relatively new model for fast manufacturing. Manufacturing operators create a three-dimensional view using CAM/CAD programs.

- Domestic supply. Leveraging a domestic supplier for material components helps reduce the sourcing and supply time, optimizing production cycles.

- Increasing order frequency. Managing bulk orders can prove beneficial to some operators. However, some clients prefer smaller batches at a higher frequency.

- Component standardization. Components are standardized to specific measurements and criteria to meet the requirements of the global economy. Operators rely on approved ISO guidelines to simplify manufacturing processes and lower production costs.

Sonic Manufacturing – PCB, Flex Circuits, and Flex-rigid Circuits

Here at Sonic Manufacturing, we use rapid manufacturing to meet production demands and fulfil customer expectations. We help R&D clients, electronic companies, and electronic product suppliers, all while using fast, rapid production processes to minimize errors, optimize costs, and ensure quick turn-around time.

When you think “fast manufacturing” in Silicon Valley, think Sonic Manufacturing! We serve the Bay Area, including San Jose, Fremont, Silicon Valley, Milpitas, Palo Alto, Mountain View.