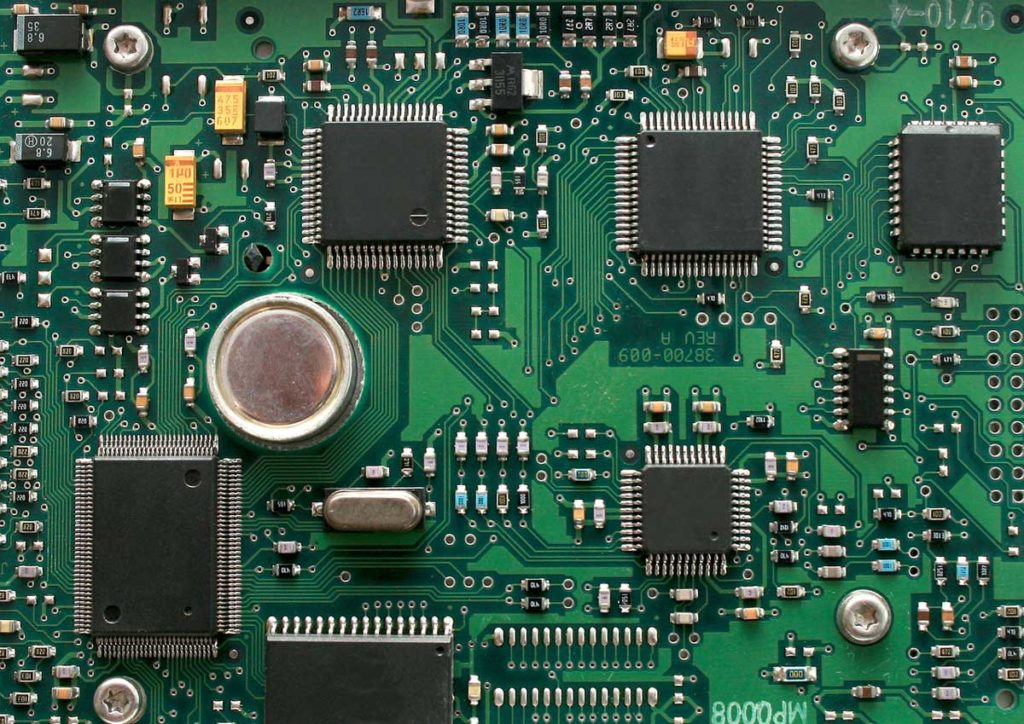

Printed Circuit Board Assembly Services

Whether you’re a San Jose engineer seeking prototyping or a Silicon Valley purchasing agent requiring full production manufacturing, Sonic Manufacturing has the equipment, knowledge, and experience for your complete printed circuit board assembly services.

We have an established track record working in a variety of industries and markets in the San Jose area and beyond:

- Automotive

- Aerospace

- Biotech and medical devices

- Computing and data storage

- Defense

- Development labs

- Industrial testing and measurement

- Internet of Things (IoT)

- Networking

- Renewable technologies

- Startups

- Wearables

Development & Prototyping

Sonic Manufacturing employs over 30 engineers with extensive development and manufacturing experience who stay in constant contact with clients. We provide a full range of support services for high-end, complex assemblies such as servers, electronic box builds, small run, and partially automated assembly projects.

The turnaround time for prototype deliveries ranges from two days to two weeks depending on project complexity and materials. We typically start with a small prototype assembly – manual or automatic – to determine the operation of a circuit or product. After that, development projects can be run through our automated assembly lines to verify manufacturability.

All of this is made possible by our advanced, state-of-the-art 85K square-foot facility in Fremont, California.

It’s custom engineered to meet New Product Introduction (NPI) requirements as well as low- and high-volume world-class manufacturing standards. This allows us to work successfully with clients in San Jose and the rest of Silicon Valley.

Printed Circuit Board Assembly (PCBA) Processes

- Double- and single-sided reflow processing

- Intrusive reflow

- Leaded and lead-free assembly

- Press fit

- Rework and repairs for fine pitch QFP and area array packages

- Surface mount technology (paste and epoxy)

- Through hole

- Water soluble and no-clean processes

- Wave and selective wave soldering

PCBA Packaging

- 01005s, BGA, uBGA, CCGA CSP, and flip chip

- 35mm fine pitch devices

- MICTOR connectors and fine pitch high-pin count press fit connectors

- Multi-layered PC board (24 layers)

- PCB surface finishes including HASL, ENIG, IS, and OSP

- Via-in-pad

PCBA Testing & Verification

After your initial printed circuit board assembly services are complete, we provide an extensive array of testing and verification processes.

- Boundary scan development and test

- Burn-in test (BIT)

- Fixture design and manufacturing

- Flying probe test (FPT)

- Functional circuit test (FCT)

- In-circuit test (ICT)

- Installation and verification

- Test program development

- X-ray inspection and 3D AOI

We also perform diagnostic and rework services with client-supplied “bone-piles” (failed ICT and FCT boards) for customers throughout Silicon Valley.

Box Builds & System Integration

We’re also available to help you take the final steps to full-scale manufacturing and assembly.

- Build-to-order (BTO) and configure-to-order (CTO) services

- Backplane assembly

- Cable and harness assembly

- Enclosures

- Engineering support

- Functional testing

- Hardware and software integration

- PCB and PCB assembly

If you’re in Silicon Valley and need electronic manufacturing services, Sonic Manufacturing has the development, management, and production expertise to provide turnkey solutions including automated supply chains and international procurement.

Need printed circuit board assembly services in San Jose? Contact us today or request a quote to learn how Sonic Manufacturing can meet your PCBA needs.

CALL FOR A QUOTE

(510) 580-8500

OR EMAIL:

Sales@Sonicmfg.com