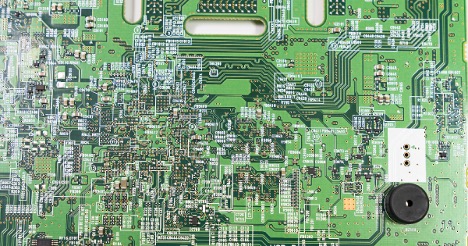

Printed circuit boards (PCBs) might not be a popular conversation starter, but they are an integral part of our day-to-day lives. Found in everything from smartphones and cars to medical devices and industrial equipment, these sensitive components are the heart of modern day electronics. However, protecting these components is critical, which is where conformal coating comes in.

Conformal coating is a thin, protective film applied to the surface of a PCB to shield it from environmental hazards. While it may be virtually invisible to the eye, the protection it offers can make all the difference in performance, reliability, and product longevity. If you are placing an order for PCBs, it helps to know what conformal coating is and why it’s a smart investment. Let’s dig in.

What Is Conformal Coating?

Conformal coating is a protective, non-conductive polymer layer that is applied over a finished PCB. It conforms to the board’s contours—covering components, solder joints, and traces—without interfering with the board’s function.

There are several types of conformal coatings, including:

- Acrylic

- Urethane

- Silicone

- Epoxy

- Parylene

Each type offers unique advantages depending on the application, but the end goal is the same: to protect the board against damage without compromising its electrical performance.

Key Benefits of Conformal Coating for PCBs

Moisture and Humidity Protection

Electronics are vulnerable to water damage—even small amounts of humidity can cause corrosion or short circuits. Conformal coating acts as a barrier that keeps moisture out, making it ideal for PCBs used in damp or high-humidity environments.

Protection from Dust, Debris, and Chemicals

Dust and contaminants can build up on circuit boards over time, leading to overheating or failure. A coated PCB is shielded from particulates, reducing the risk of electrical leakage or arcing.

In industrial settings, PCBs may be exposed to oils, solvents, or corrosive gases. Urethane and epoxy coatings, in particular, offer robust protection against chemical attack, preserving the integrity of the board.

Improved Dielectric Strength

Conformal coating increases the PCB’s dielectric strength—meaning it can handle higher voltages without breakdown. This is especially valuable in high-voltage or high-frequency applications.

Thermal and UV Resistance

Certain coatings (like silicone and parylene) offer resistance to extreme temperatures and UV exposure, making them suitable for outdoor or aerospace applications.

Extended Product Life

By shielding the board from physical and environmental stressors, conformal coating helps extend the operational lifespan of the electronics—resulting in fewer repairs, less downtime, and better customer satisfaction.

Common Applications for Conformal Coating

Conformal coatings are used in a wide range of industries, including:

- Automotive electronics (ECUs, sensors)

- Aerospace and defense systems

- Medical devices

- Consumer electronics

- Telecommunications

- Industrial control systems

In any application where reliability is critical, conformal coating adds an important layer of security.

Is Conformal Coating Always Necessary?

No, not every PCB requires conformal coating. However, many do. The Sonic Manufacturing team recommends conformal coating when devices are exposed to harsh environments, when long-term reliability is essential, and when repairs or replacements are costly or difficult to make (e.g., aerospace or implanted devices).

Conclusion: Small Layer, Big Protection

Conformal coating might be thin—but its impact is huge. By defending PCBs from moisture, debris, chemicals, and mechanical wear, it helps ensure electronics run reliably and efficiently in even the toughest conditions. Whether you’re producing consumer gadgets or mission-critical systems, conformal coating offers peace of mind—and a solid return on investment.

Need help choosing the right conformal coating for your PCBs? Reach out to Sonic—we will make recommendations based on your application, environment, and performance needs.