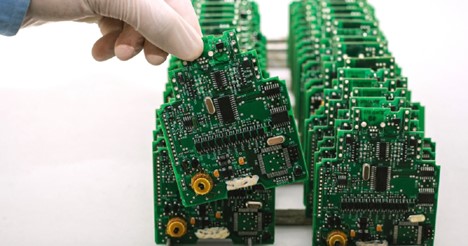

Proper Thermal Management in PCB Development and Manufacturing

There’s no question that printed circuit boards (PCBs) are the essential framework that all electronic components rely on. As these devices become more powerful and compact, managing the heat generated by the internal components becomes a major concern. Without proper thermal management, it’s possible for electronic devices to overheat, leading to reduced performance, shorter lifespans, or even complete failure.

Working with an experienced PCB manufacturer helps avoid the pitfalls of improper thermal management. Sonic Manufacturing Technologies not only understands the importance of thermal management in PCB design, but we utilize industry-standard strategies for materials, layout and product selection that ensure optimal heat dissipation.

Why Thermal Management Matters

Every electronic component on a PCB assembly generates heat when in operation. As the density of components on PCBs increases, so does the heat output. If this heat isn’t efficiently managed, it can lead to several issues:

- Performance Degradation. Excessive heat can cause components to operate outside of their ideal temperature range, leading to slower processing speeds and less efficient performance.

- Component Failure. Overheating can permanently damage components, leading to malfunctions or total failure of the device.

- Reduced Lifespan. Even if components don’t fail immediately, prolonged exposure to high temperatures can shorten their overall lifespan, leading to early breakdowns and increased maintenance costs.

- Safety Concerns. In extreme cases, inadequate thermal management can result in fire hazards or explosions, particularly in high-power applications.

Given these risks, effective thermal management is crucial to the reliability, safety, and longevity of electronic devices.

Key Strategies for Thermal Management in PCB Design

There are several strategies PCB designers can employ to manage heat effectively. The first is material selection. Using materials with high thermal conductivity, such as copper, is ideal as this ensures the PCB’s traces and vias dissipate heat more efficiently. Thermal interface materials (TIMs) are also used between components and heat sinks to enhance thermal conduction. These materials fill in the small air gaps that would otherwise impede heat transfer.

Optimizing PCB layout is another crucial factor. Strategically placing components that generate the most heat away from each other and near the edges of the board can help prevent hotspots. Thermal vias also play a vital role in managing heat by allowing heat to pass through to other layers. Finally, using large copper plans, particularly ground and power planes, can act as heat spreaders, distributing heat across a larger area and reducing the temperature of individual components.

Additional strategies for thermal management include the use of heat sinks and heat spreaders for distributing heat evenly and active cooling solutions like fans and liquid cooling systems to move more air across the PCB. Before finalizing the PCB design, engineers often use thermal simulation software to model heat distribution and identify potential issues.

The Future of Thermal Management in PCB Design

As electronic devices continue to evolve, becoming smaller yet more powerful, the challenges of thermal management will only intensify. Emerging technologies, such as advanced cooling techniques and the development of new materials with even higher thermal conductivity, will play a crucial role in addressing these challenges. Additionally, as more devices integrate artificial intelligence and machine learning, there may be opportunities to develop self-regulating thermal management systems that can adapt in real-time to changing conditions. Time will tell!

Sonic Manufacturing: Adhering to Quality Standards

Thermal management is a critical aspect of PCB design that directly impacts the performance, reliability, and safety of electronic devices. By carefully selecting materials, optimizing layouts, and employing both passive and active cooling methods, designers can ensure that heat is effectively managed, protecting components from damage and extending the life of the device. For a free quote, contact Sonic Manufacturing Technologies today. We are strategically located in Silicon Valley with the largest EMS in the Valley, and we follow the highest standards to ensure zero-defect products.