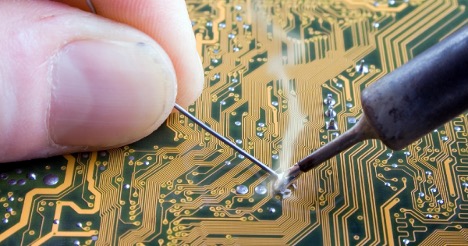

Solder is an important part of PCB assembly (PCBA). It’s a special type of material (usually a metal alloy mixed of tin, lead, and other metals) that physically and electrically connects components to the board. Solder melts at relatively low temperatures, acting as a strong “glue” that bonds components to the copper pads or holes on the board.

Once the solder is dry, it forms a durable, conductive path that allows electrical signals to flow between components. While solder is a crucial part of PCBA, it can be messy to work with, especially if it’s not used correctly. For example, it can splatter and cause short circuits. However, there is such a thing as “no-clean solder,” which can make a big difference in production efficiency and final product performance.

Let’s learn more about what no-clean solder is so that you know what to ask for in your next PCB project!

What Is No-Clean Solder?

No-clean solder, or no-clean flux, is a type of soldering material that is designed to leave behind very little residue after the soldering process. Any residue that is left is chemically stable, non-conductive, and safe to remain on the board without causing corrosion, electrical interference, or aesthetic problems. Because the residue is minimal and safe, cleaning the PCB after soldering is usually unnecessary, hence the name no-clean.

How Does No-Clean Solder Work?

During soldering, flux plays an important role. It removes oxidation from metal surfaces and helps the molten solder bond securely to the component leads and PCB pads. Traditional fluxes often leave behind a sticky, corrosive residue that must be removed through cleaning (usually with solvents or water-based solutions).

No-clean solder, by contrast, uses a specially formulated flux that burns off cleanly or leaves behind only a very thin, benign layer. This eliminates the need for an extra cleaning step after assembly, saving time, labor, and costs.

Key Benefits of No-Clean Solder

As you can imagine, there are many benefits to using no-clean solder. While there is nothing inherently “wrong” with using traditional solder, extra attention must be given to avoid a messy environment. For instance, you need the right soldering iron, temperature, and flux, and you need to clean the iron tip and use isopropyl alcohol after to remove flux and splatter from the board. In some cases, desoldering materials are required to remove excess solder or correct blobby joints. No-clean solder takes away a lot of these inconveniences and offers the following advantages:

- Reduced Manufacturing Costs: Since no extra cleaning is needed, production times are faster and operating costs are lower.

- Improved Workflow: No-clean processes simplify manufacturing, especially for high-volume PCB production.

- Less Risk of Damage: Cleaning steps can sometimes introduce moisture or damage delicate components. Skipping cleaning altogether reduces that risk.

- Compliance with Standards: Most no-clean solders meet IPC industry standards for reliability and safety when used properly.

When to Use No-Clean Solder

No-clean solder is not ideal for every situation. In cases where the final product must meet strict visual standards, such as aerospace or medical devices, additional cleaning might still be required. The same is true for electrical components where even the tiniest traces of residue could cause a problem.

The following generally do not benefit from no-clean solder:

- Consumer electronics (phones, laptops, TVs)

- Industrial controls

- Automotive electronics

- Applications where aesthetics are not critical (or where light residue is acceptable)

- High-volume manufacturing where time and cost savings are priorities

Are There Any Drawbacks?

While no-clean solder offers many advantages, it’s important to be aware of the limitations. For instance, there is the possibility of residue visibility. Some customers prefer a spotless board appearance, and no-clean flux can leave slight discoloration or haze that’s visible under certain lighting.

Another drawback is post-processing challenges. If you ever need to rework or modify a board later, the remaining flux residue might interfere with soldering unless it’s cleaned first. Lastly, no-clean flux might attract moisture in humid or corrosive environments, eventually affecting performance.

Is No-Clean Solder Right for You?

No-clean solder has become a go-to solution for many PCB manufacturing projects because it simplifies the assembly process, cuts costs, and reduces the risk of contamination.

However, like any material choice, it’s important to match the solder type to the demands of your specific project. A reputable PCB manufacturer can help you decide whether no-clean solder or another soldering approach is the best fit based on your design, performance requirements, and industry standards.

At Sonic, we work closely with our customers to select the right materials and processes for success. If you have questions about no-clean solder or PCB assembly, we’re here to help! Contact us today at 510-826-5406 to learn more!