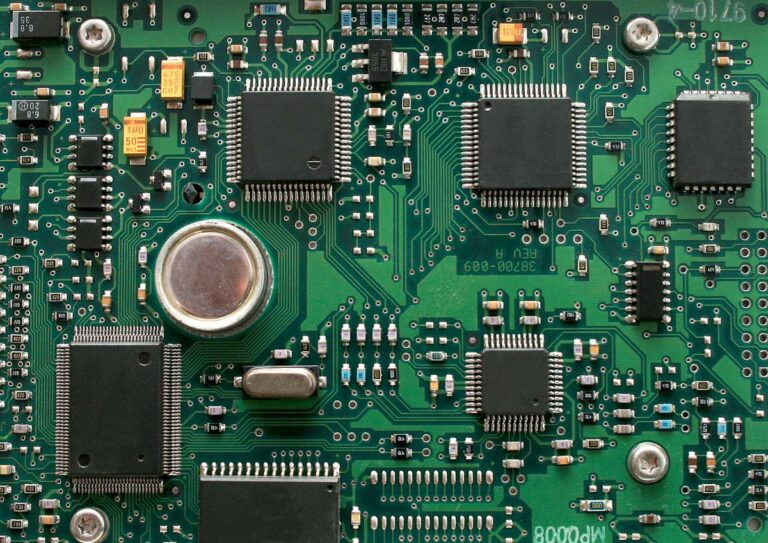

In most printed circuit board assemblies (PCBAs), every component is critical to its performance. The process used to source, purchase and schedule approved components has an impact on the final build’s time to customer, as well as possibly its quality.

Across the world, there is continued growth in the manufacturing base of PCBAs as much as 6% over the next two years. In this blog, we’ll discuss why supply chain management is now more important than ever for PCBA contractors.

3 Ways Supply Chain Management is Vital for PCBA Contractors

The effects of globalization combined with intermittent and unexpected disruptions are pushing supply chain logisticians to the brink. The timely sourcing of quality components requires a robust supply chain strategy with proven results to answer customer demand.

Here are the top three SCM considerations to keep in mind when choosing a PCBA contractor today.

1. Global Sourcing and Procurement Capabilities

With more component manufacturers now available, having a global sourcing and procurement strategy with a wide network of suppliers should be one of the first considerations when assessing PCBA contractors.

PCBA contractors need supply chain management to:

- Provide components with shortened lead times on product orders

- Conduct the necessary quality assurance on each component and supplier

- Source components according to the applicable standards (IPC, ISO, or MIL-Spec) of the BOM

- Maintain adequate volumes even with changes in demand forecasts

2. Maintains the Accuracy of BOMs

A PCBA contractor should have a change management system in place that quickly adapts and tracks changes to a bill of materials (BOM) for each production run.

Changes to a BOM should:

- Reflect a like-for-like replacement in components that adds value to the manufacturing process (time, cost, or efficiency)

- Include potential replacement components before production starts to ensure all parts are of the same quality when switching suppliers

- Use a controlled process and record management system to ensure all BOMs and Gerber files reflect each product batch when leaving the facility

3. Uses an Agile Manufacturing and Supply Chain Process

Finally, a quality PCBA contractor will have an agile manufacturing and supply chain logistics process to help your business succeed. Changes in forecasts, returns, and repairs, and passive stock management should be part of the service the contractor provides.

Look for a PCBA manufacturing contractor with an agile SCM service that can handle your inbound or return logistics.

Partner with PCBA and Supply Chain Experts at Sonic Manufacturing

Sonic Manufacturing has a team of experts available who can help any product team achieve new efficiencies and ensure SCM quality at every stage. From product assembly to prototyping and new product introductions (NPIs), Sonic can assist with all your logistical strategies, manufacturing planning, and component sourcing needs.

Sonic helps product teams from our offices in Fremont and can handle your manufacturing needs in San Jose, Sacramento, Oakland, Silicon Valley, South San Francisco, Burlingame, Salt Lake City, or the Bay Area.

To find out how Sonic can help you improve your supply chain management as your PCBA contractor, get in touch by calling (510) 580-8500 or emailing us at sales@sonicmfg.com today.