Sonic utilizes strategic planning, cutting-edge equipment, and specialized expertise to deliver superior PCB assembly and manufacturing services. Our flexible processes and thorough testing ensure dependable products tailored to your exact specifications.

BGA Pitch Production

Developmental BGA Pitch

Blind & Buried Vias for

Rigid, Rigid Flex, and Flex

Components Placed Daily

Our engineering team collaborates closely with you to ensure an efficient development process. Sonic’s partners work with program managers to build prototypes to your specifications and timeline. We address first-time build inquiries quickly and efficiently, working around the clock to meet your objectives.

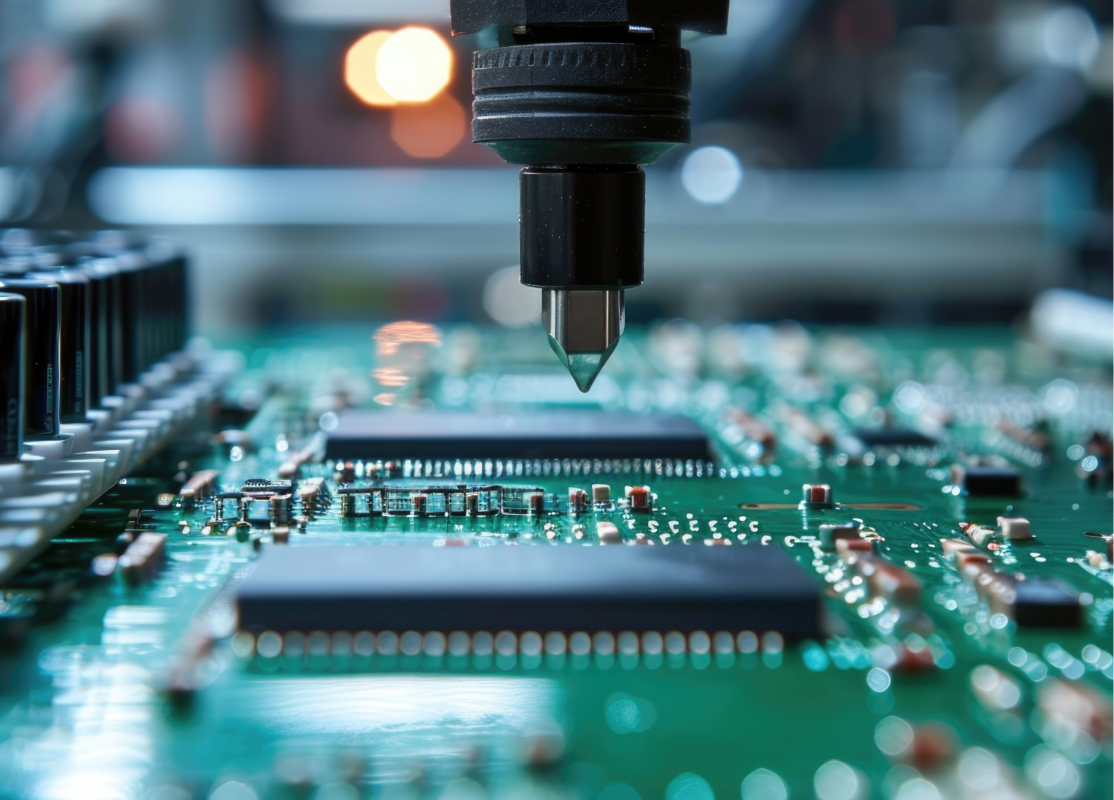

Precision SMT with paste and epoxy for high-quality assembly.

Reliable through-hole technology for robust connections.

Secure press fit connections for various applications.

Expert rework and repairs for fine pitch and BGA array packages.

Compliant leaded and lead-free assembly options.

Efficient reflow soldering for complex assemblies. Custom fixtures to ensure efficient reflow soldering.

High-quality wave/selective wave soldering for mass production.

Reflow processing for single and double-sided boards.

Both water-soluble and no-clean assembly processes.

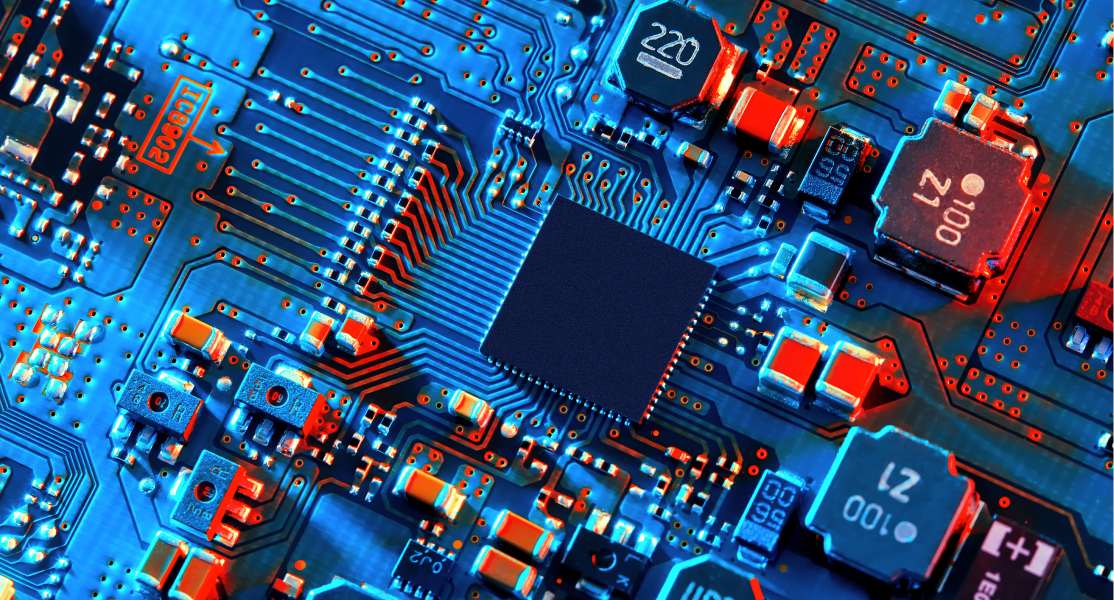

Sonic’s expertise includes a wide range of components, ensuring precise placement and reliability on PCBs. Our team regularly works with the following package types, maintaining the highest standards of quality and performance.

Sonic’s testing team ensures our clients receive products of the highest quality and long-term reliability. We utilize Sonic standard test equipment and customized functional testers to guarantee product performance and longevity. Sonic works with its clients and builds a robust test strategy for the customer with the following vehicles:

Utilizes cutting-edge equipment and facilities for precise assembly, ensuring high-quality production.

Over 25+ years of expertise in PCB manufacturing, driven by a skilled and knowledgeable team.

Rigorous testing with state-of-the-art equipment ensures reliability.

Achieves prototype to production in as little as 2-10 days with efficient workflows and dedicated resources.

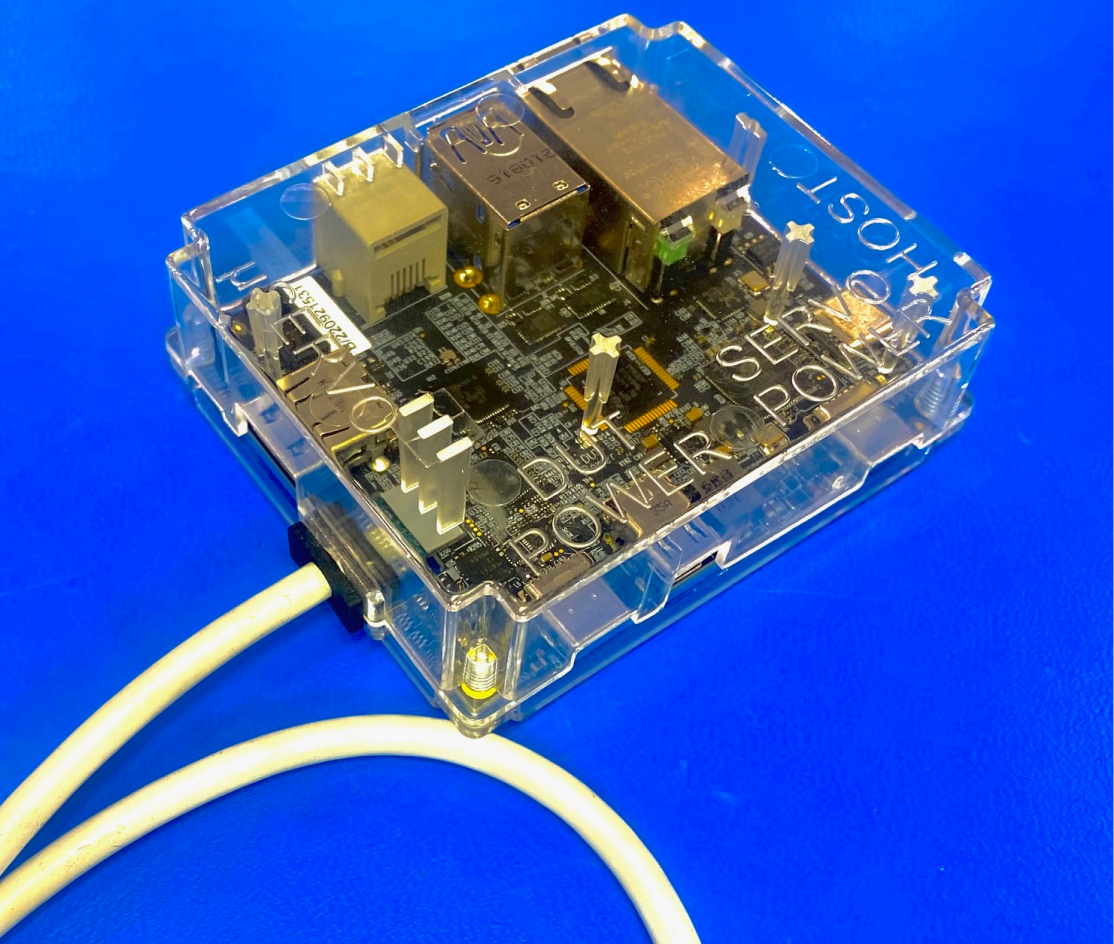

Sonic provides integration services that support today’s innovative and unique business models. We develop customer specific processes, tracking and testing of sub-systems and finished products. We work with standard and custom-designed enclosures, in addition to small and large form factors.

Calling is the fastest way to receive a quote. We have professionals at our facilities ready to process your requests at any moment during regular business hours.

The second fastest way to receive a quote is by filling out our simple form. A request will be sent straight to our quote department to be processed within 24 hours.