With all the challenges facing the electronic manufacturing industry, cost and time as competitive strengths at Sonic Manufacturing Technologies help keep your business on a profitable track. Rising costs, long lead times, and access to talent are the chief concerns for product teams according to data from IPC.

In the IPC survey, respondents reported:

- Rising material and labor costs are stifling profits and limiting growth

- Inventories remain low due to electronic manufacturing supply chain disruptions

- Recruiting qualified technicians and engineers remains an industry-wide challenge

Slowing growth across the sector is another issue that firms will have to contend with over the next two years. Within this economic climate, there are ways that you can still succeed with your new product introduction (NPI), prototyping, and supply chain efforts. Sonic Manufacturing has the technical expertise, industry experience, and an optimized manufacturing process that will help you thrive while others struggle to survive.

How Sonic Provides Competitive Strength with Cost and Time Optimization

Sonic works with established teams and startups who need to improve manufacturing operations. ‘Not only is cost a competitive strength for Sonic Manufacturing Technologies, but time is as well.’

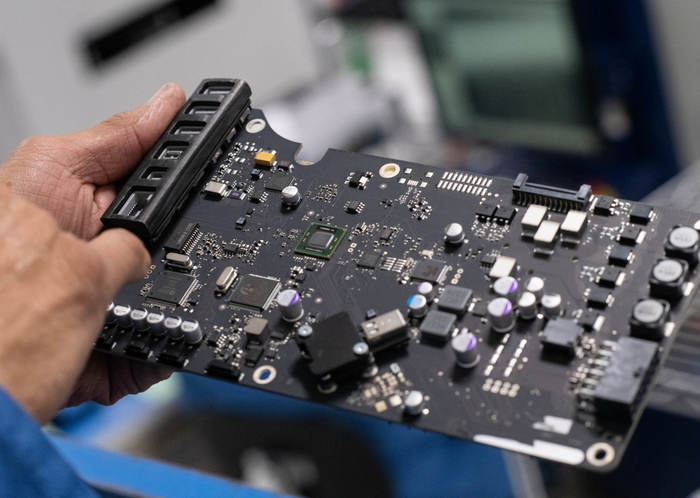

Shortening your time to market for NPIs, rapid turnarounds for new prototypes, and maintaining the required inventory depends on having a contract manufacturer with PCBA utilization capacity built for speedy execution.

At Sonic, we deliver streamlined electronic manufacturing services:

- Highly automated Fremont, CA state-of-the-art PCBA and electronic assembly facility

- Prototyping new product designs on live production lines to optimize for DFM and DFT

- Maintaining passive stores that enable shortened turnarounds from order to product delivery

- Sourcing most components with HAL, our automated supply chain solution

- Managing inventory demand by providing shortened production runs that keep up with your forecast changes

Cost and Time as a Competitive Edge with Sonic Manufacturing

Sonic Manufacturing understands that you value the speed of execution, and we can turnaround your product prototypes in as little as one day. Our engineers use the latest CAD and IM tech to streamline the entire PCB assembly, box build, and system integration processes that your product depends on.

If you want to improve inventory management, increase your cash-flow runway, and speed up new product development, we’ve built a manufacturing process that doesn’t just reduce costs but enables faster execution. We use state-of-the-art manufacturing techniques to deliver quickly, within spec, and according to the certifications you need to comply with your industry standards.

Compete on Cost and Time with Sonic Manufacturing Technologies

Cost effective and time efficient assembly solutions are competitive strengths at Sonic and the top priority for our engineers and technical staff. We get information back to engineering quickly and turn prototypes into full production runs within the shortest timeframes. Our inbound and outbound logistics services keep your products flowing as the market demands and with full engineering support from start to end.

To discuss how we can assist you to compete on time and cost in the challenging electronics manufacturing industry today, reach out to Sonic by filling out this form.